A Detailed Guide to What is Die Cutting, Its Types & Applications

Waqas Khan Pitafi 2024-07-26 07:59:27

Die-cutting is widely used in packaging, printing, and labelling. According to a report by Business Research Insights:

“The global market size of die cutting machines was valued around USD 1.1 billion in 2022”

This huge volume is because die cutting is one of the most efficient paper and cardstock cutting techniques. It can shape many materials like cardstock, paper, rubber, foam, and more according to your requirements.

The finesse and quality of the shapes made using this technique are matchless. Whether you are looking to make sharp edges of your packaging or curved ones, a die cut machine can help.

In this blog, we will discuss a detailed guide to what is die cutting, its important types, and its applications. Read on to find more!

What is Die Cutting?

Die cutting is one of the most popular cutting, shearing, and shaping methods in the packaging, printing, and label industries. The two vital aspects of this method include cut and die. In this process, custom packaging, stickers, labels, and other similar objects are cut in specific shapes according to dielines (outlines drawn to guide the cutting direction).

What is a Die?

Die is a metallic tool that comes in the same shape as your required cut design. Dies possess sharp edges that effortlessly cut various materials with utmost finesse, giving objects an accurate and captivating shape.

Types of Dies

Many types of dies are available to shape your packaging, labels, and stickers. Here are some popular types that are commonly used in the market:

- Steel-Rule Dies: They are highly popular for cutting objects like packaging, labels, and stickers because they can make sharp borders and edges. The durable steel makes these dies excellent for cutting sturdy packaging like rigid boxes.

- Clear Cutting Plates: Two transparent dies are used to sandwich the material you want to cut. These dies are excellent for cutting intricate designs.

- Plastic Shims: Inexpensive yet durable dies that perfectly fit in the cutting machine to shape thin objects like cardstock or kraft packaging.

- Magnetic Shims: Other types of dies may be displaced when they pass through the machine. However magnetic shims stick to their place firmly and help cut the part without getting displaced.

History of Die Cutting

The die cutting process was primarily invented in the shoemaking and leather industry in the mid-1800s. This cutting method was designed to streamline the cutting process of leather shoe soles. However, it used to be expensive as well as laborious.

In the early 1900s die-cutting technology advanced, and helped cobblers craft shoes without much effort. Also, the widespread use of die-cutting technology was understood but not common. In 1977, Bob and LaDorna Eichenberg made the first die cutting machine that people could use to cut different objects in their desired shapes.

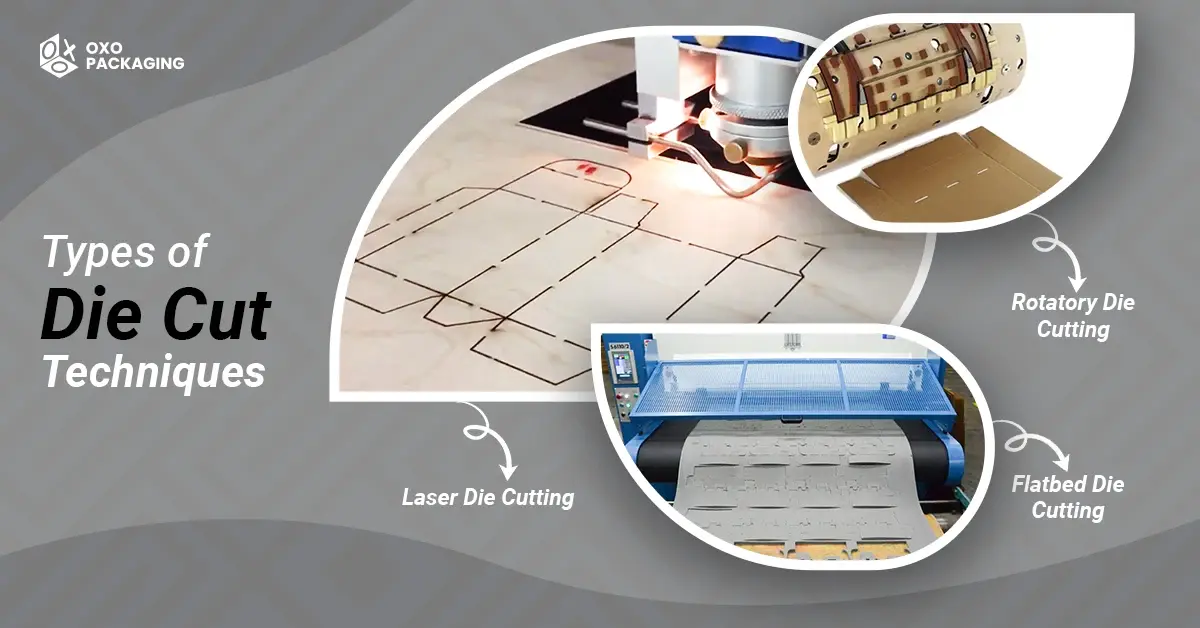

Types of Die Cut Techniques

Now, as we know Die Cut techniques are used for shaping many objects according to your preferences, let’s delve into the types of Die Cutting techniques. Here are three of the most popular methods used to cut and design custom packaging and other items:

-

Rotatory Die Cutting

Rotatory die cutting is one of the most efficient methods that help cut multiple and regular shapes instantly. A revolving metal die keeps rotating in this method, and a flex, cardstock, or other object passes under it.

The die is in the form of cylinders and is incorporated with sharp blades. The optimized speed of the rotating die decides the lengths of the shapes. This method is often the first choice when it comes to high-volume cutting.

-

Laser Die Cutting

When it comes to cutting with utmost precision on flexible items like forams and rubbers, laser die cutting becomes the first choice. One of the best things about this method is it caters to cutting all the details, even tiny holes and fenestrations as well.

Many types of laser-cutting machines are available in the market, however, two are the most popular. One is a sheet-fed gantry laser more suitable for small-scale cutting. The other is a web-fed in-line laser cutting machine appropriate for large-scale cutting.

-

Flatbed Die Cutting

Where the rotatory cutting fails, flatbed die cutting comes into the game. It is an excellent method to cut shapes for low-volume projects. One of the best things about this cutting method is that it can cut significantly thicker sheets without any hassle.

Flatbed dies are fabricated according to your preferred shapes. The sheets needed to cut are placed under the dies. Afterwards, the dies are placed under presses (mostly mechanical, or hydraulic). Once cutting is done, the press and dies are removed and the final shapes are easily drawn away. It is one of the most economical Die Cutting techniques.

Types of Die Cutting Machines

Die-cutting machines are available in many types. Each type is famous for its distinctive features and applications. Two of the most popular types are as follows:

- Manual Machine: The die-cutting machines have steel-cutting dies that are manually activated with the help of a lever. They are perfect for home use.

- Digital Machine: Digital die cutting machines require a computer cartridge that contains an image. This machine uses a sharp blade to cut materials instead of a steel die.

Applications of Die Cutting

As discussed above, the market volume of Die Cutting machines is significantly high. This is because they have a wide application in multiple industries. Some of the common applications of Die Cut are listed here:

-

Custom Packaging Boxes

The significance of die-cutting cannot be denied in the packaging industry. This machine is used to shape foldable boxes, custom bags, and other types of packaging. Being economical, packaging manufacturers can easily use this cutting method at a large scale to make custom packaging solutions for product-selling businesses.

The Die Cut method can also be used to add some enticing elements to packaging boxes that enhance the visual appeal of these packaging boxes. For instance, packaging manufacturers can use this technique to add custom windows to their packaging boxes.

-

Stickers, Cards & Labels

Stickers, cards, and labels are an efficient marketing tool for many businesses. All of them are shaped uniquely using an efficient die-cutting technique. Stickers and labels are mostly small in size and made of thin cardstock and paper stock, so they can be easily made using rotary die cutting.

On the other hand, birthday, business, and other cards need significant customizations. Manufacturers prefer flatbed dies to shape these cards.

-

Foam, Rubber & Plastic

Many types of rubber parts in the automotive industry are shaped using die-cutting. Engine seals and rubber gaskets are commonly designed using Die Cut techniques.

Many die-cutters can cut thin sheets of plastic and make an array of products. Also, these cutters have significant use in cutting many types of foam. Die-cut foam can help make insulation, gaskets, and more.

Tips for a Perfect Die Cut

Getting perfect results out of die-cutting is important for packaging manufacturers. Improvising your cutting method and getting sharp edges and ideal shapes can be challenging. Consider these tips to get quality die cutting for your packaging, labels, and stickers:

- Place the objects on plates such that both stick together during cutting to avoid errors due to the displacement of objects.

- If you want to add holes, leave ample distance between holes and edges of the material to prevent stock from tearing away.

- Extending artwork or color pattern printing is recommended to avoid unusual white spaces after cutting is done.

- Don’t forget to add dielines to the stock before cutting. These lines seamlessly guide you through the cutting process.

Importance of Dielines in Die-Cutting

Dielines are the straight lines drawn near the border of flat packaging box templates. They can be categorized into three types based on their lines: cut lines, fold lines, and dotted perforation lines. They are mostly drawn by the designers of custom packaging.

The prime purpose of dielines is to give directions to cutters or printers to shape and design the packaging boxes perfectly. These lines play a significant role in precisely cutting the custom packaging borders to give your desired shape and size. That’s why their importance in die-cutting can never be overlooked.

What is Die Cutting in Printing?

Die Cutting in printing is used to add elegant designs to papers, labels, cardstocks, and more. Dies cut the printed part on the surface of paper or cardboard showcasing unique die-cut designs on their surface. It is an excellent technique to enhance the visibility of printed imagery and graphics on your packaging, stickers, and labels.

This technique can also be used to cut the surfaces of these materials in the shape of your brand logo. This way you can boost your brand and fascinate your prospects.

Where to Get Die Cut Services for Custom Packaging?

If you are looking for a reliable packaging partner who offers top-tier die-cutting services, get in touch with OXO Packaging. All you need to do is share your designs and requirements with us. We will cater to the dies and plates required to make your perfect die-cut boxes or labels for your business. Reach out to us for an instant quote today!

Conclusion

Die Cutting is a method used to shape many materials like paper, cardstock, and more according to your preferences. In this technique, metal dies are shaped according to your required design.

This blog has covered in detail everything you need to know about the innovative and most efficient Die Cut technique. If you are still confused, you can drop your query in our email. We are here to answer your question.